Highest quality

Engine injectors

Engine injectors are the parts of the fuel system of the engine that directly spray fuel into the engine cylinder.

The injector is an integral part of the fuel injection system, which:

- feeds the fuel under appropriate pressure into the combustion chamber,

- ensures appropriate fuel spraying

In indirect injection systems, the most popular injector design are pintle injectors.

In direct injection systems, the most popular injector design are multi-hole injectors.

The injectors are integrated with the following:

- in-line injection pump

- distributor injection pump

The injector is connected to the pump by a high-pressure line.

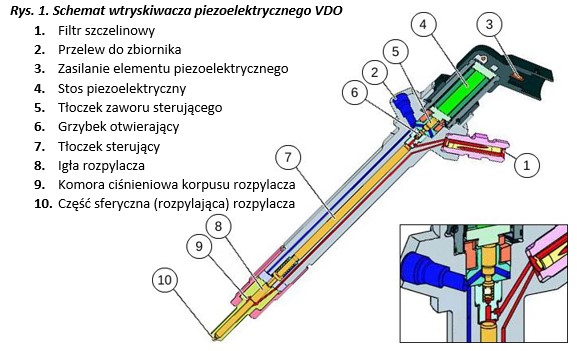

Due to the development of new forms of hydraulic fuel injection systems and increasingly stringent environmental requirements to be met by contemporary diesel engines, modern fuel injection methods have become dominant in contemporary diesel engine designs. In the latest systems, direct injection of fuel increasingly uses piezoelectric injectors instead of electromagnetic injectors.

In the case of systems with a swirl chamber or pre-combustion chamber, fuel is compressed by an in-line or rotary fuel pump to the pressure of approx. 200 bar and fed directly into the injector using metal lines. Design of a standard injector:

- slot filter

- fuel passage

- pressure pin

- adaptor plate

- nut

- nozzle cap

- nozzle body

- locating dowels

- spring

- adjustment shim

- overflow channel

- overflow port

- injector body

- threaded connection

- sealing cone

The role of the injector in the modern diesel engine and the impact of its efficiency on the proper operation of the engine and the exhaust gas treatment system

The vast majority of currently produced diesel engines used to drive various types of vehicles are equipped with common rail injection systems. This type of power system, developed over the last twenty years, allows for advanced control of the combustion process of the mixture in the combustion chamber of a diesel engine.

A very important design modification of this type of injection system in relation to the older generation design is the ability to maintain a constant, high pressure throughout the entire fuel injection period, well above 1000 bar and often even 2500 bar. Increasing the fuel injection pressure allowed for a significant reduction in the time needed to deliver the required amount of fuel to the combustion chamber, which translated into a reduction in the injection time in its individual phases.

The technical modifications made it possible to significantly reduce the noise and vibrations of the diesel engine with direct fuel injection. This significantly increased the efficiency of the combustion process, which resulted in an increase in torque and power while reducing fuel consumption. These changes have made it possible for this type of engine to be widely used in small passenger cars and vans. Obtaining such advanced control of the combustion process in the cylinder also allowed for the installation of exhaust gas treatment systems – catalytic converters and diesel particulate filters – in compression ignition engines. This made it possible to significantly reduce the emission of toxic substances. A key issue for reliable engine operation throughout its service life is to maintain stable fuel supply performance for as long as possible. The injection system of a diesel engine is one of the most sensitive and vulnerable components of a vehicle. The most frequently damaged are the injector’s precision vapours, i.e. dosing valves and nozzles responsible for delivering a properly atomized dose of fuel to the appropriate places in the combustion chamber. These are parts exposed to the destructive effects of adverse factors occurring in the combustion chamber, which can lead to deterioration of the operational and ecological parameters of the combustion engine.

When the diesel engine is running, the electronic control unit checks the rotational speed of the crankshaft by measuring its angular acceleration during the stroke of each cylinder and strives to ensure that these values are equal. This parameter is adjusted by changing the opening time of the injector. As a result, the amount of fuel supplied to the combustion chamber increases or decreases. The correct dosing of fuel by the injector is directly related to its technical condition, and in particular to the wear of the atomizer. Any damage to the injectors can have a very negative impact on the efficiency of the engine and its peripheral systems. Each nozzle, which is the most important element of the injector, has the right number of spray holes with a dedicated shape and position required for the proper shaping of the fuel stream in the combustion chamber. A disruption in the flow changes the amount of fuel injected, which has a direct impact on the increase in exhaust emissions. As a result of the impact of unfavourable physico-chemical conditions prevailing in the combustion chamber and the forces occurring as a result of the intensive cooperation of the components of the precision steam, the process of wear of the nozzle and changes in its basic parameters responsible for tightness, correct direction of feeding and fuel dosage occurs. The atomized fuel should go directly into the combustion chamber, which is located in the piston. If the fuel is fed to the wrong points in the combustion chamber or is atomized incorrectly, the piston or valves may be thermally damaged. Often, due to the high combustion temperature, the atomizer itself is destroyed. Such faults can contribute to a serious engine failure resulting in the need for major repairs or costly rebuilds of the exhaust aftertreatment system.

The condition of the injection system in a modern combustion engine, in particular the injectors, must be periodically verified for the sake of proper operation. In this way, you can protect the engine and its accessories from serious failures that require large financial outlays to restore its full operational efficiency. Bearing in mind the importance of the atomizer for the proper operation of the injector, the quality of the components used in the regeneration process is important for the effectiveness of restoring its factory parameters during repair. Therefore, the right choice of spare parts supplier seems to be crucial. One of the leading manufacturers of atomizers on the global market is WUZETEM.

It is a Polish company with nearly 70 years of tradition, which supplies about 500,000 pieces per year. spare parts for customers in the automotive industry dealing with professional regeneration of injection systems for diesel engines. Nozzles manufactured by WUZETEM are a high-quality alternative to products supplied by original equipment manufacturers. Tests of fuel equipment are carried out in a state-of-the-art laboratory, where all functions of the nozzle responsible for the proper formation of the mixture in the diesel engine are evaluated.

In the production of the offered spare parts, the factory uses steel from recognized, certified, European manufacturers. The manufacturing processes use state-of-the-art mechanical, heat and thermo-chemical treatment technologies comparable to those used by manufacturers of original equipment parts. The company uses advanced measurement techniques that allow the product to be evaluated with accuracy of less than one micrometer, guaranteeing the highest quality of the precision pairs offered. Between 2002 and 2010, the company cooperated with Delphi Diesel System, supplying parts for the injection system for the first assembly in Fiat and Peugeot cars. In addition, the company is a manufacturer of engine injectors of an older design.